Need a Helping Hand? Isabella did, so we did our best to help her out. I first met Isabella back in April 2015. I was manning a stand at a EUL Docklands Open Day and i’d made arrangements to meet her there, with her mother and uncle. I wasn’t too sure what to expect, I’d been a member of the Enabling the Future (enablingthefuture.org) volunteer community helping people to be fitted with a prosthetic hand, for over a year, but this was the first real contact I’d had with a recipient.

Isabella was born with Symbrachydactyly, which is a congenital (present at birth) hand anomaly,  which affects a single upper limb.It is characterised by short,stiff, webbed or missing fingers.The underlying muscles, tendons,ligaments and bones are all affected. This occurs in one out of 32,000 births.

which affects a single upper limb.It is characterised by short,stiff, webbed or missing fingers.The underlying muscles, tendons,ligaments and bones are all affected. This occurs in one out of 32,000 births.

Isabella is a bit of a character. Instantly likeable and a very bubbly personality, she seems to take her disability in her stride. I took some measurements and, using the Hand-0-matic tool on the E-nable website, I created a set of files and got printing!

Now her original request was to make it colourful, but the initial files produced gave me a hand that would fit me (I’m 53 and she’s 8), so the scaling was a bit out. But the downside was that it used all my pink filament!

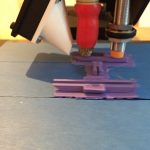

Next I went for a thermoformed gauntlet (forearm piece). It prints flat and then, when heated in in  boiling water, can be formed around the arm, making a better fit. Then I used this gauntlet and scaled it to fit the palm and the fingers. The result was a nice, black, silver and gold hand in Colorfabb filament.

boiling water, can be formed around the arm, making a better fit. Then I used this gauntlet and scaled it to fit the palm and the fingers. The result was a nice, black, silver and gold hand in Colorfabb filament.

Isabella and Mark, her dad, popped over to my house on a Saturday morning and we thought we’d give it a try. Looking nice is one thing, being practically useful is something completely different.

We sat in my kitchen and strapped the hand on for the first time. We checked the padding, the tension on the screws and then, finally, we were ready for a trial run. By flexing her wrist she was able to open a close the fingers. That worked fine so now it was time to try and pick something up. We didn’t want anything breakable or too heavy, so we settled on a plastic spray oil container.

We sat in my kitchen and strapped the hand on for the first time. We checked the padding, the tension on the screws and then, finally, we were ready for a trial run. By flexing her wrist she was able to open a close the fingers. That worked fine so now it was time to try and pick something up. We didn’t want anything breakable or too heavy, so we settled on a plastic spray oil container.

The result was a complete success and she took the hand home. It made the local press, Evening Standard, BBC South West and ITV news. Mark has made some post-fitting changes to improve the fit and the grip and she’s been getting on like wildfire.

I saw her again, last Saturday, as it’s been getting on for 6 months now, and I wanted to see how she was getting on. The current hand still fits okay, but there have been some more recent design changes from the fantastic designers involved with Enabling the Future, so we’re going to have a look at a few of those to see if we can come up with something new for her.

Because of that, I thought we’d try and cast a copy of her hand using Alginate and Plaster of Paris. We had some fun, mixing and casting and came up with the picture on the left.

Because of that, I thought we’d try and cast a copy of her hand using Alginate and Plaster of Paris. We had some fun, mixing and casting and came up with the picture on the left.

To be honest, I was really surprised how it came out, but it did feel a little bit on the fragile side, so I got my Occipital Sensor scanner out and ran a quick scan and the printed a plastic copy for day-to-day testing and fitting.

I have to say that, with the technology available today, the whole process from casting to scanning to printing was completed in a number of hours.

I have to say that, with the technology available today, the whole process from casting to scanning to printing was completed in a number of hours.

The technology from companies such as Printrbot, Occipital (and Apple) and Filament from Colorfabb (and others) made all this available to makers and tinkerers and, hopefully, will enable e-nable hands to be fitted to more people.